R&D prototype is always a very tight tolerance prototype Machining. This is a Research development project from a printer device company, it is 1 unit with totally 15 parts, which requires the precision machined parts from CNC. This project will use for the functional test and Dependency checking.

Services: CNC Machining

Materials: Black ABS

Finish: Polishing

Unit: 1 unite included 15 parts

Lead Time: 8 days

Project Processing

The structure of the printer prototype is not that especially complicate for machining projects, however, that structure with the high precision requirement is the tough thing for most of the 3-axes CNC machining Company. We use a newly precision CNC machine combined with the special programming processing and skilled operation to process this prototype testing unit.

Some aperture or positioning dimension requires a limited tolerance of 0.05mm which is a challenge for plastic machining. We had designed a lot of positioning fixtures using in CNC Machining, on one hand, to make the possibility to process the model in one whole part, and on the other hand, prevent the plastic out of shape during processing. Repeated measuring during processing is a must step as well. Finally, we will provide a 100% whole dimension measuring report to clients.

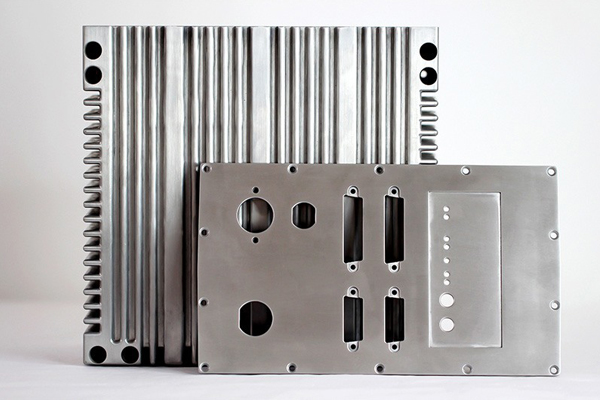

Radio Equipment Case

Radio Equipment Case

Automotive Air Conditioner Control Panel

Automotive Air Conditioner Control Panel